Shape-Memory Effect in Olefin-Copolymers and Heterogeneous Blends

The goal of the project is the systematic investigation of the relation between structure and the shape-memory (SM) effect polymers. In particular, the project focuses on the description of basic mechanisms of the thermal-induced SM effect in cross-linked semi-crystalline polymers and the development of polymer blends with multiple SM effect. Thermally induced SM effect in such polymers appears properly with high performance, if at temperatures above melting point of crystalline phase and by large deformation, the covalent network firstly produces sufficiently large visco-elastic forces and secondly shows a good stability i.e. high enough elongation at break and preferably lowest permanent set. At the same time the crystalline phase, which is formed after cooling of loaded sample, must be able to fix efficiently the visco-elastic forces stored in network. As model polymers are employed cross-linked metallocene-catalyzed ethylen-1-alkene copolymers of different structure, crystallinity, and melting temperatures which can be well controlled by the alkene content. Multiple SM polymers can be generated by formation of cross-linked copolymers or polymer blends with several crystalline phases and/or crystal populations with different melting temperature. Hence, in present study the SM behavior of cross-linked binary and ternary blends on the basis of ethylen-1-octene copolymers (EOC) with other polyolefins like HDPE and iPP are investigated. The influence of programming, which includes also temperature–triggered changes of crystallinity, and network parameter on the shape-memory behavior by mentioned ethylene copolymers and blends will be analyzed. The results of the project contribute to better understanding of correlations between structure, programming parameters and SM behavior for process optimization. Furthermore, the results serve for development of innovative SE polymers and theirs suitable applications.

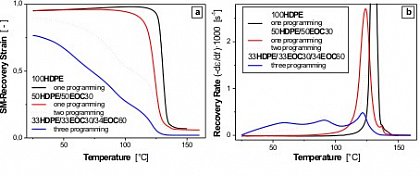

The temperature dependencies of the SM recovery strain epsilon rec (a) and recovery rate d epsilon rec/dt (b) illustrate the influence of the programming parameters on the shape-memory behavior of a binary and a tertiary blend on basis of HDPE and EOC with degree of branching of approx. 30 and 60 CH3/1000C (EOC30 and EOC60), respectively. All materials were cross-linked by liquid peroxide (2,5-dimethyl-2,5-di-(tert.butylperoxy)-hexane. Like cross-linked HDPE and EOC, the epsilon rec(T) and d epsilon rec(T)/dt curves of blend samples show only a single step or peak, respectively, i.e. a single answer temperature, Tres , if the sample was loaded only at a single temperature (e.g. Tpr=140°C and programming strain epsilon pr = 100 % for HDPE and 50HDPE/50EOC30 blend). By contrast, binary 50HDPE/50EOC30 and ternary 33HDPE/33EOC30/34EOC60 blends exhibit in each case two or three steps, or peak in epsilon rec(T) and d epsilon rec(T)/dt diagrams, respectively, if the samples were programmed at two or correspondingly three temperatures (in present case: Tpr1 = 140 °C, epsilon pr1 = 44 %, Tpr2 = 90 °C, epsilon pr2 = 56 % for 50HDPE/50EOC30 blend and Tpr1 = 130 °C, epsilon pr1 = 30 %, Tpr2 = 85°C, epsilon pr2 = 33 %, Tpr3 = 50 °C, epsilon pr3 = 37 % for 33HDPE/33EOC30/34EOC60 blend)

Relevant Publications:

Hai Hong Le, Osayuki Osazuwa, Igor Kolesov, Sybill Ilisch, Hans-Joachim Radusch: Influence of carbon black properties on the Joule heating stimulated shape-memory behavior of filled ethylene-1-octene copolymer, Polymer Engineering & Science, 51 (3) (2011) 500–508

H.H. Le, I. Kolesov, Z. Ali, M. Uthardt, O. Osazuwa, S. Ilisch, H.-J. Radusch

Effect of filler dispersion degree on the Joule heating stimulated recovery behavior of nanocomposites

Journal Material Science (2010) DOI 10.1007/s10853-010-4664-7 (http://www.springerlink.com/content/m236m73656v73735/fulltext.pdf

I.S. Kolesov, H.-J. Radusch: Multiple shape-memory behavior and thermal-mechanical properties of peroxide cross-linked blends of linear and short-chain branched polyethylenes,

eXPRESS Polymer Letters 2 (2008) 461–473

(Available online at www.expresspolymlett.com)